Objectives of Paper:

- Reduction of vibration

- reduction of acoustic noise

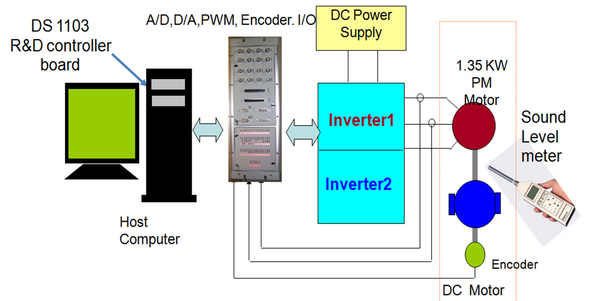

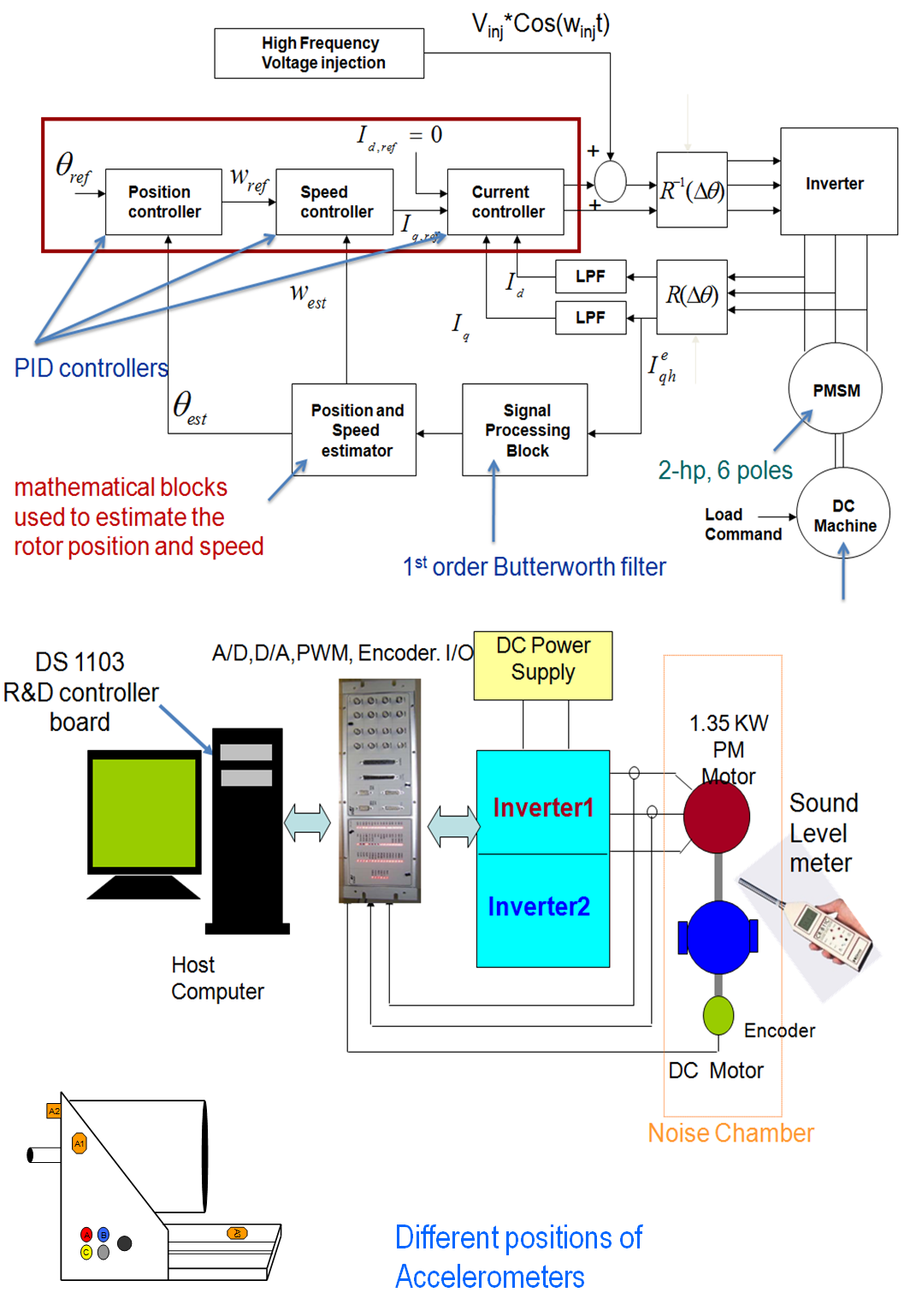

Sensorless control of PMSM at low speed:

- Motor is excited by fluctuating voltage carrier signal Vinj Cos(wt)

- High frequency impedance is measured.

- Excitation signal is injected in stationary reference frame

- Based on inductance variation due to rotor saliency.

How is it Done:

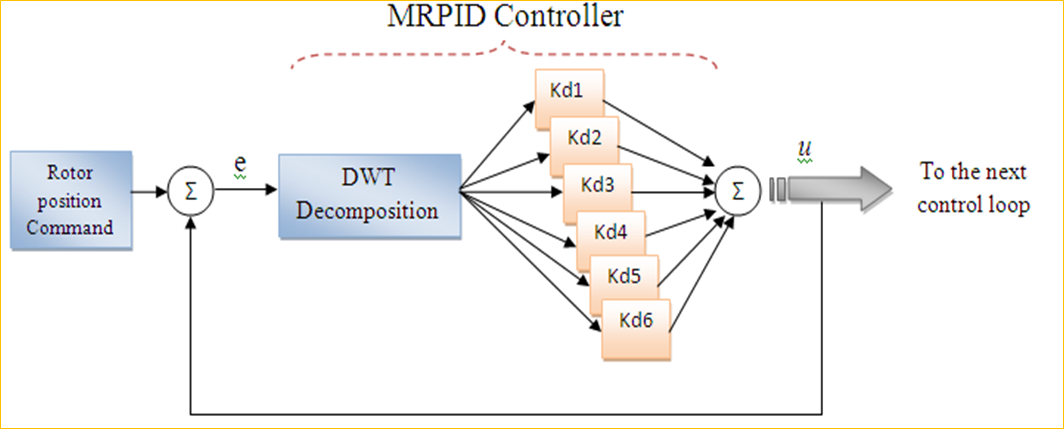

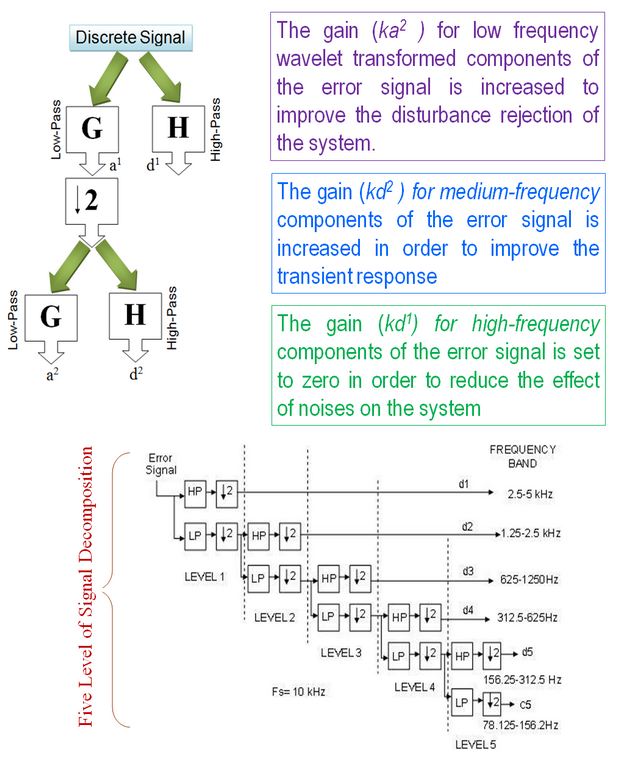

Multi-Resolution Controller:

- The use of wavelet transform

- Error Signal decomposition

Parameters tuning:

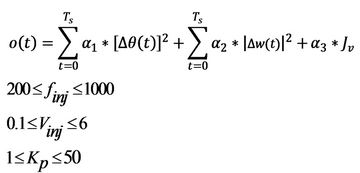

Online optimization problem formulation:

Gains ![]() are used to tune high and medium frequency components of the error signal

are used to tune high and medium frequency components of the error signal

Online optimization problem formulation:

0.01< {Kd1, Kd2, Kd3} <10

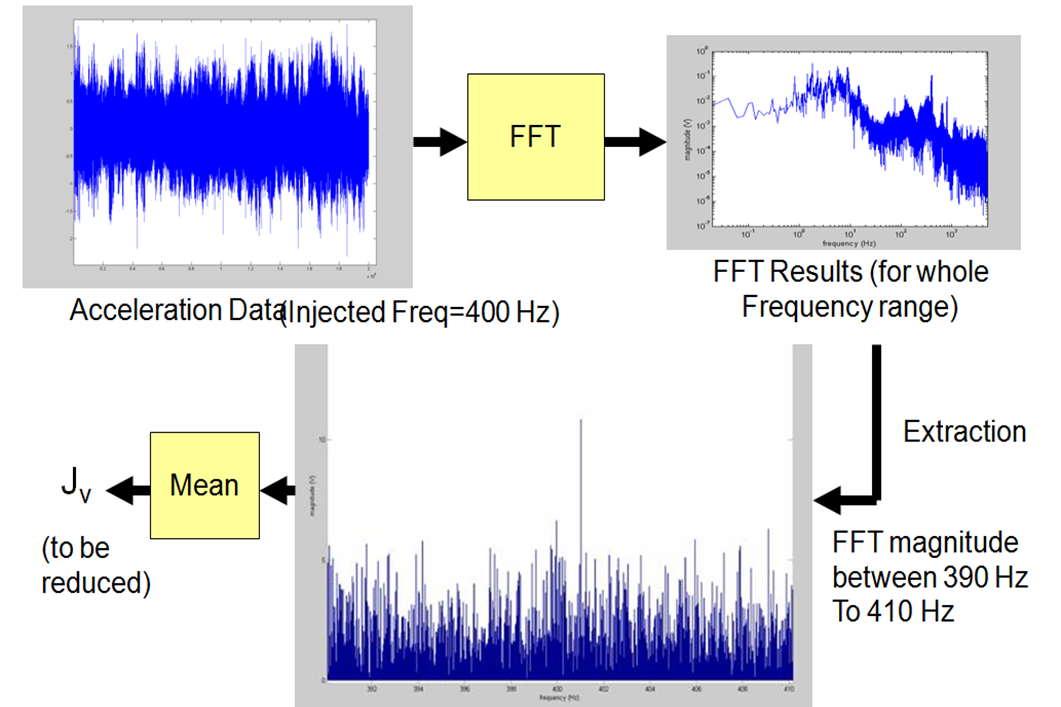

How Jy is calculated?

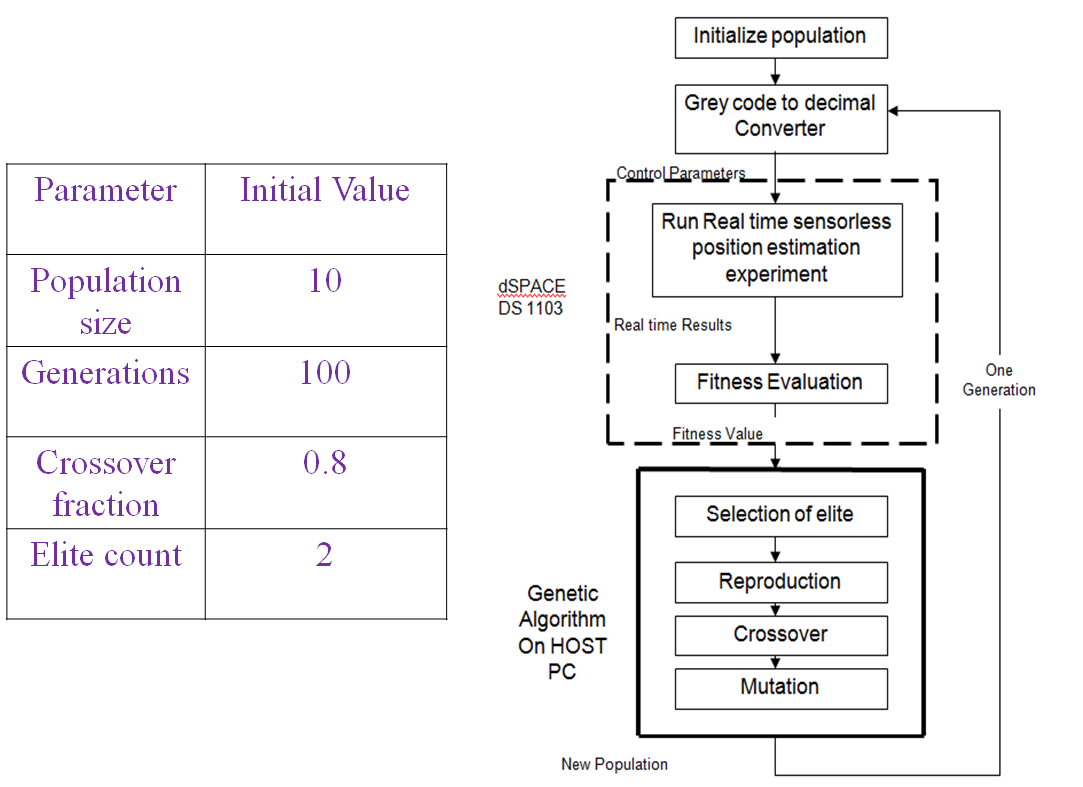

Procedure of Optimization with hardware in the loop:

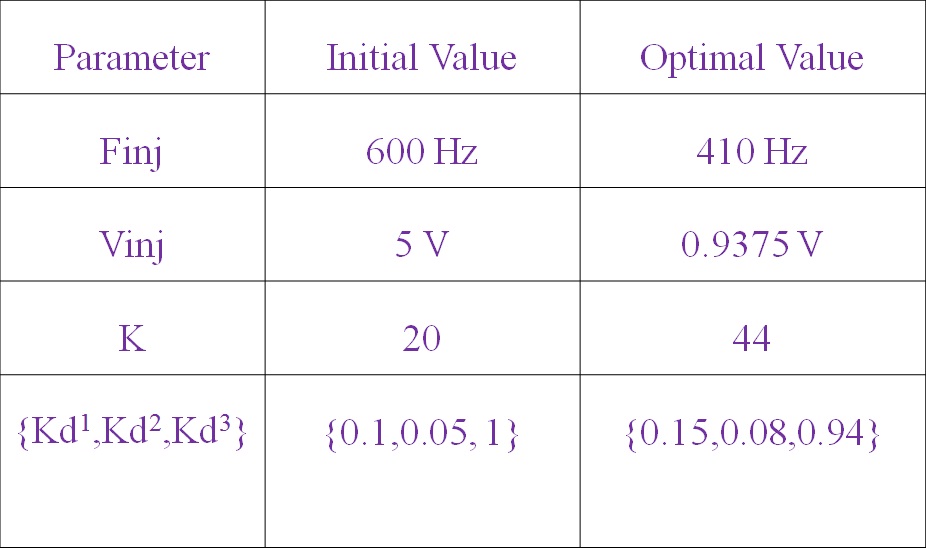

Optimization Results:

Experimental Results:

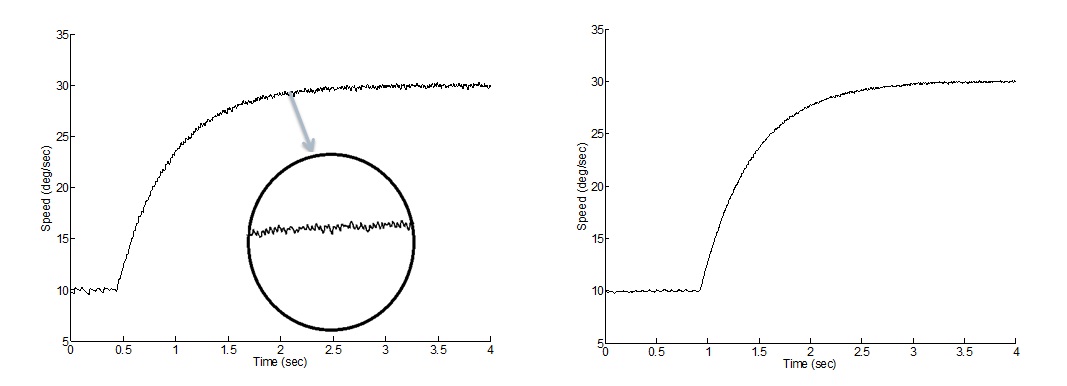

Speed controller response to a step change in the reference speed from 10 to 30 deg/sec

fig: Before optimization fig: After optimization

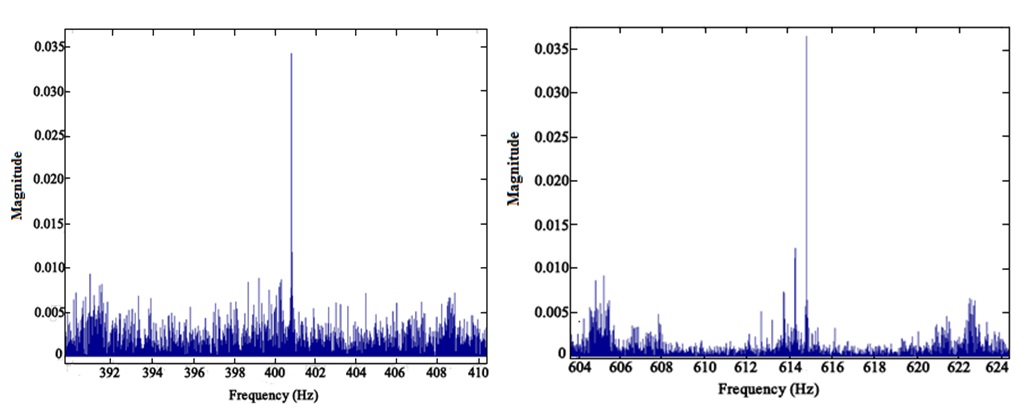

FFT Analysis of the Accelerometer Results:

fig: Axial vibration before optimization fig: Axial after optimization

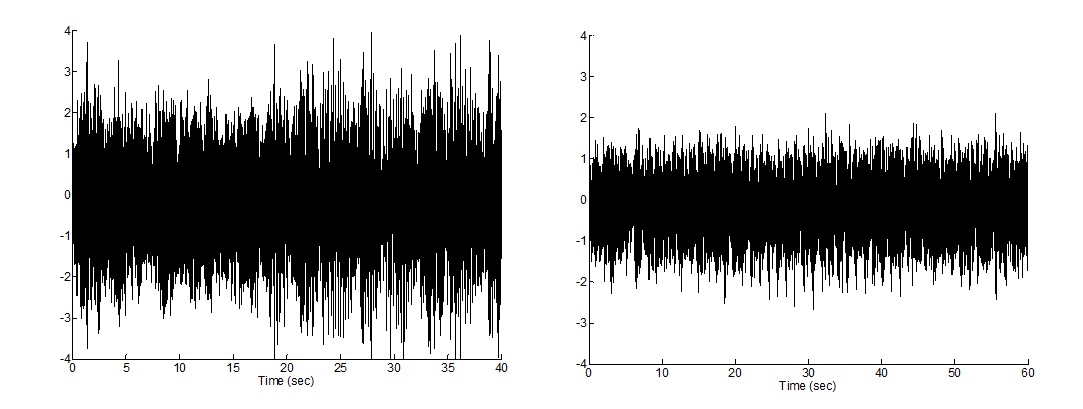

Noise Measurements of the PM Motor using Axial & Radial Accelerometer:

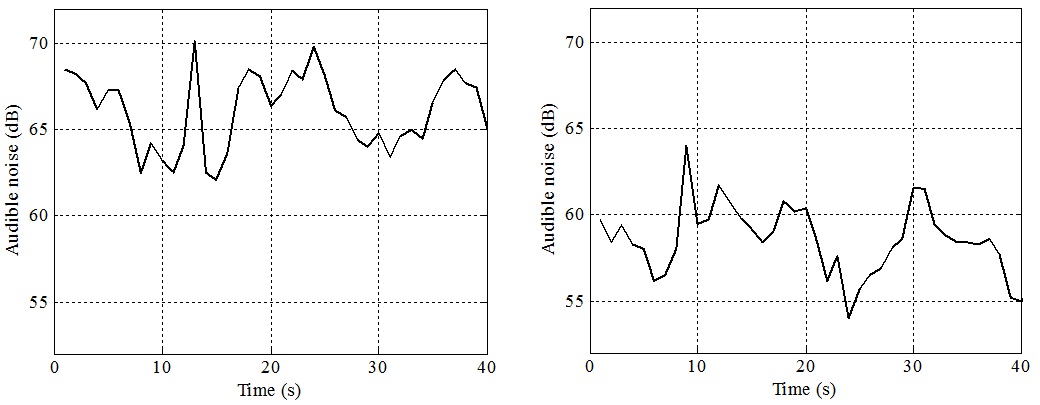

Audible Noise Measurement:

Conclusion:

- Axial & Radial Vibration are reduced (up to 10%)

- Steady state Error is reduced (up to 5%)

- Smooth operation of the motor is obtained

- Motor produces less amount of audible noise (up to 18%)